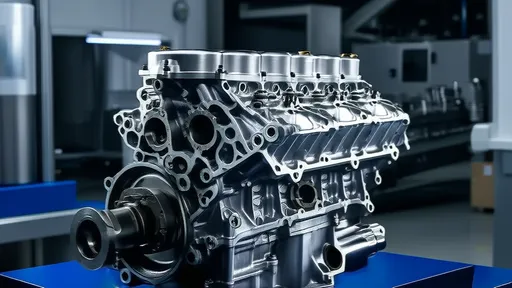

The internal combustion engine, a marvel of engineering that has powered humanity for over a century, finds itself at a crossroads. As the world shifts toward electrification, engineers are squeezing every last drop of innovation from piston engines. Variable compression ratio (VCR) technology emerges as perhaps the most sophisticated attempt to extend the relevance of traditional powertrains in an increasingly battery-dominated landscape.

At its core, VCR represents an elegant solution to an ancient compromise. Since Nikolaus Otto's first four-stroke engine, designers have wrestled with the compression ratio dilemma - high ratios deliver efficiency but risk destructive knocking, while low ratios sacrifice thermal efficiency for reliability. Modern turbocharging exacerbates this tension, forcing engineers to design around worst-case scenarios. Variable compression shatters this paradigm by dynamically adjusting combustion chamber geometry to match operating conditions.

The mechanical ballet required to achieve this feat borders on alchemy. Nissan's VC-Turbo engine, the first production VCR system, employs a multilink mechanism that subtly alters piston top dead center. A harmonic drive actuator continuously adjusts the multi-link's pivot point, enabling compression ratios between 8:1 (for high-boost performance) and 14:1 (for lean cruising). This mechanical complexity would have been unthinkable before computer-controlled actuators and advanced metallurgy.

What makes VCR particularly compelling is its dual personality. During gentle highway cruising, the engine transforms into an Atkinson-cycle miser, extracting maximum work from each fuel molecule. When the driver demands acceleration, the system morphs into a short-stroke powerhouse, swallowing turbo boost without detonation. This chameleon-like behavior closes much of the efficiency gap between conventional engines and hybrids.

The environmental implications are profound. Independent testing reveals VCR engines can reduce real-world fuel consumption by 15-20% compared to fixed-ratio counterparts. When paired with mild hybridization, these powertrains approach the well-to-wheel efficiency of some plug-in hybrids, especially in highway-dominant driving patterns where batteries struggle to contribute meaningfully.

Yet for all its brilliance, VCR arrives at a curious historical moment. Automakers are pouring billions into electrification, with some announcing complete phaseouts of internal combustion. The technology's complexity - requiring additional moving parts in an industry desperate to simplify - makes it a tough sell. Nissan's VC-Turbo, while technically impressive, has seen limited adoption across model lines, suggesting manufacturers view it as a niche solution rather than a wholesale revolution.

Material science breakthroughs may hold the key to VCR's future. New high-temperature alloys and coatings could reduce the reliability penalty of additional moving parts. Meanwhile, computer-controlled hydraulic systems might replace some mechanical linkages, reducing friction losses. Some engineers speculate about "digital VCR" systems using electromagnetic valve actuation to effectively alter compression characteristics without physical geometry changes.

The economic calculus remains challenging. Developing a VCR engine costs substantially more than refining conventional designs, and these costs must be recouped in a market where premium buyers increasingly prefer electric vehicles. Still, for markets with poor charging infrastructure or heavy reliance on synthetic fuels, VCR could buy crucial time in the transition to carbon neutrality.

Perhaps VCR's greatest legacy will be as a technological bridge. As synthetic fuels and hydrogen combustion gain traction, the ability to adapt compression ratios becomes even more valuable. These alternative fuels often require radically different combustion characteristics than gasoline, making flexibility paramount. In this light, VCR may evolve rather than disappear, becoming a key enabler for sustainable liquid fuels.

The story of variable compression ratio technology mirrors that of the internal combustion engine itself - a masterpiece of mechanical ingenuity fighting to remain relevant in a digital age. Whether it becomes a footnote in automotive history or the foundation for a new generation of ultra-clean engines depends as much on policy and infrastructure as on engineering brilliance. For now, it stands as a testament to how much life remains in the century-old piston engine concept when pushed to its intellectual limits.

By /Jun 15, 2025

By /Jun 15, 2025

By /Jun 15, 2025

By /Jun 15, 2025

By /Jun 15, 2025

By /Jun 15, 2025

By /Jun 15, 2025

By /Jun 15, 2025

By /Jun 15, 2025

By /Jun 15, 2025

By /Jun 15, 2025

By /Jun 15, 2025

By /Jun 15, 2025

By /Jun 15, 2025

By /Jun 15, 2025

By /Jun 15, 2025