The formation of metallic glasses, a unique class of materials with disordered atomic structures, has long fascinated researchers due to their exceptional mechanical properties and resistance to crystallization. At the heart of this phenomenon lies the interplay between atomic packing density and critical cooling rates, a relationship that dictates the glass-forming ability (GFA) of metallic alloys. Recent advances in experimental techniques and computational modeling have shed new light on how these factors conspire to either promote or inhibit the formation of stable amorphous phases.

When molten metal cools below its melting point, the system faces a thermodynamic race against time. Crystalline phases, with their regular atomic arrangements, represent the equilibrium state that nature prefers. However, if the cooling occurs rapidly enough to outpace the kinetics of crystal nucleation and growth, the liquid structure becomes frozen into a metastable amorphous solid. The critical cooling rate required to achieve this glassy state varies dramatically among different alloy systems, spanning several orders of magnitude from 106 K/s for marginal glass formers to as low as 0.1 K/s for bulk metallic glasses.

Atomic packing density emerges as a crucial parameter influencing this critical cooling rate threshold. Densely packed atomic configurations in the liquid state exhibit slower atomic diffusion and higher viscosity, creating inherent resistance against rearrangement into crystalline lattices. This concept builds upon the classical free volume theory, where reduced atomic mobility in tightly packed systems directly correlates with improved glass-forming ability. Experimental evidence shows that alloys designed with optimized atomic size ratios—typically involving three or more constituent elements with significant size mismatch—tend to achieve higher packing densities in their supercooled liquid states.

The connection between packing efficiency and GFA becomes particularly evident when examining the temperature dependence of viscosity. Systems with high packing densities demonstrate a pronounced increase in viscosity upon cooling, following a non-Arrhenius behavior described by the Vogel-Fulcher-Tammann equation. This rapid viscosity growth effectively slows down atomic motion, making it increasingly difficult for crystalline nuclei to form and grow before the liquid becomes immobilized. The fragility parameter, which quantifies how sharply viscosity changes with temperature, has been shown to correlate strongly with measured critical cooling rates across various metallic glass systems.

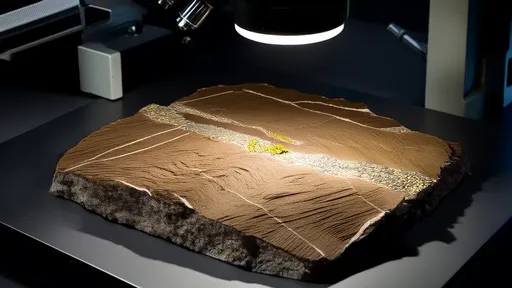

Recent high-energy X-ray diffraction studies have provided unprecedented insights into the structural origins of these packing effects. By analyzing the partial pair distribution functions of multicomponent alloys, researchers have identified characteristic features in the medium-range order (2-5 Å) that distinguish good glass formers from poor ones. Specifically, systems exhibiting more homogeneous atomic environments with efficient local packing tend to require lower critical cooling rates. This observation supports the "confusion principle," where chemical complexity and dense packing work synergistically to frustrate the formation of periodic crystalline structures.

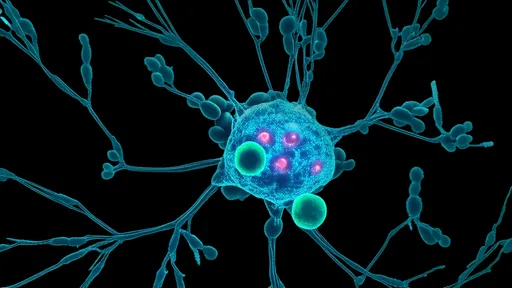

Computer simulations have complemented these experimental findings by revealing the dynamic heterogeneities in supercooled metallic liquids. Molecular dynamics studies show that in systems with high packing density, the atomic motion becomes increasingly cooperative as temperature decreases. These string-like collective motions, involving dozens of atoms moving in concert, create temporary voids that enable structural relaxation without leading to crystallization. The characteristic timescale of these cooperative rearrangements relative to the cooling rate appears to be a key determinant of glass-forming ability.

The practical implications of understanding this critical relationship extend beyond fundamental materials science. By establishing quantitative correlations between measurable packing parameters and critical cooling rates, researchers can now design new alloy compositions with enhanced GFA without exhaustive trial-and-error experimentation. This knowledge has already led to the development of several novel bulk metallic glass systems with critical casting thicknesses exceeding 10 mm, opening doors for structural applications that were previously unthinkable for amorphous metals.

Looking ahead, challenges remain in fully quantifying how subtle variations in atomic packing translate to precise predictions of critical cooling rates. The next frontier involves developing multi-scale models that can bridge the gap between atomistic simulations and macroscopic processing conditions. As characterization techniques continue to improve, particularly with the advent of fourth-generation synchrotron sources and advanced electron microscopy, researchers are poised to uncover even deeper connections between local structure, atomic dynamics, and the glass formation process.

What makes this field particularly exciting is its interdisciplinary nature, combining elements of physics, chemistry, materials science, and engineering. The fundamental insights gained from studying metallic glasses often find parallels in other glass-forming systems, from polymers to colloidal suspensions. As our understanding of the packing-cooling rate relationship matures, it may well lead to a unified theory of glass formation that transcends specific material classes.

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025