Molecular Self-Assembly: Nature’s Blueprint for Spontaneous Order from Nanoscale to Macroscale

The natural world is a master of organization, effortlessly crafting intricate structures without external guidance. At the heart of this phenomenon lies molecular self-assembly—a process where disordered components autonomously arrange themselves into ordered, functional systems. From the double helix of DNA to the iridescent scales of a butterfly’s wing, self-assembly bridges the gap between the invisible nanoworld and the tangible reality we experience daily. Scientists are now decoding these principles to revolutionize materials science, medicine, and nanotechnology.

The Silent Choreography of Molecules

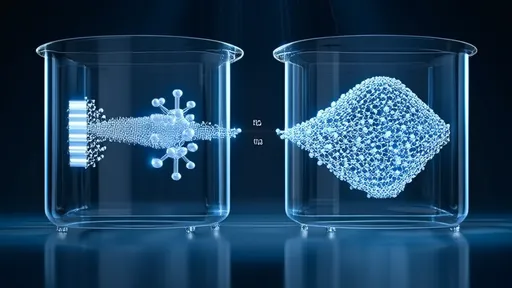

Self-assembly occurs when molecules, driven by non-covalent interactions like hydrogen bonds or van der Waals forces, find equilibrium in precise configurations. Unlike top-down manufacturing, which carves order from bulk materials, self-assembly is a bottom-up approach where complexity emerges from simplicity. Consider lipid bilayers: these dynamic membranes form spontaneously in water, their hydrophobic tails shunning the aqueous environment while hydrophilic heads embrace it. This delicate balance mirrors how soap bubbles stabilize—a macroscopic echo of molecular behavior.

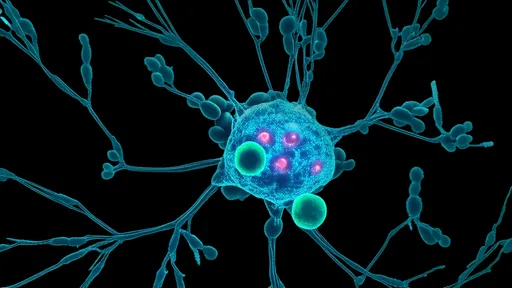

What makes self-assembly extraordinary is its scalability. Quantum dots can organize into crystalline arrays for solar cells, while proteins fold into enzymes with atomic precision. Even larger systems, like virus capsids, assemble from protein subunits with near-zero error rates. Such efficiency dwarfs human-made assembly lines, hinting at untapped potential for industrial applications.

Harnessing Chaos to Create Order

Researchers manipulate self-assembly by designing "molecular recipes"—tailoring environmental conditions (pH, temperature) or engineering complementary shapes (lock-and-key interfaces). DNA origami exemplifies this: synthetic strands fold into nanostructures by pairing predictable base sequences. Meanwhile, block copolymers—chains of chemically distinct segments—spontaneously phase-separate into nanoscale patterns useful for semiconductor lithography.

Challenges persist, however. Entropy often fights order, and defects can propagate. Yet nature thrives on imperfection; seashells grow resilient through self-correcting mechanisms. Scientists now mimic these strategies, developing error-tolerant systems. For instance, supramolecular polymers reconfigure dynamically, healing fractures autonomously—a property coveted for self-repairing materials.

From Lab to Reality: Macroscopic Manifestations

The leap from nano to macro demands innovative approaches. 3D printing with self-assembling inks allows scaffolds for tissue engineering to organize cell growth. Photonic crystals, inspired by opals, manipulate light via colloidal particles that arrange themselves during evaporation. Even architecture explores programmable cement where minerals crystallize into load-bearing forms.

Perhaps the most striking example is liquid crystals—ubiquitous in displays yet rooted in self-assembly. Their alignment shifts with electric fields, enabling pixels. Similarly, researchers engineer microrobots that swarm like birds, responding to chemical gradients. These feats blur the line between biology and engineering.

Ethics and Future Horizons

As control over self-assembly grows, so do questions. Synthetic lifeforms could solve environmental crises but risk ecological disruption. Military applications of self-healing materials or camouflaging surfaces raise dual-use concerns. Transparency in research and public dialogue will shape responsible innovation.

The next decade may see self-assembling vaccines targeting mutating viruses or carbon-capture sponges designed from peptide networks. By embracing nature’s playbook, humanity steps closer to sustainable fabrication—where order arises not from force, but from the quiet intelligence of molecules finding their place.

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025

By /Jun 19, 2025